Bidirectional rope switch

The pull rope switch is installed on both sides of the belt conveyor and connected with a steel wire rope. When an emergency occurs in the conveyor belt equipment, the steel wire rope is pulled at any location along the site. The steel wire rope drives the drive arm to rotate, and the precision cam is displaced by the torque spring driven by the transmission shaft. The micro switch is driven to cut off the control line, and the conveyor stops running. Release the steel wire rope, and the switch contacts will automatically return to the original set position.

- HFKLT2-1

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

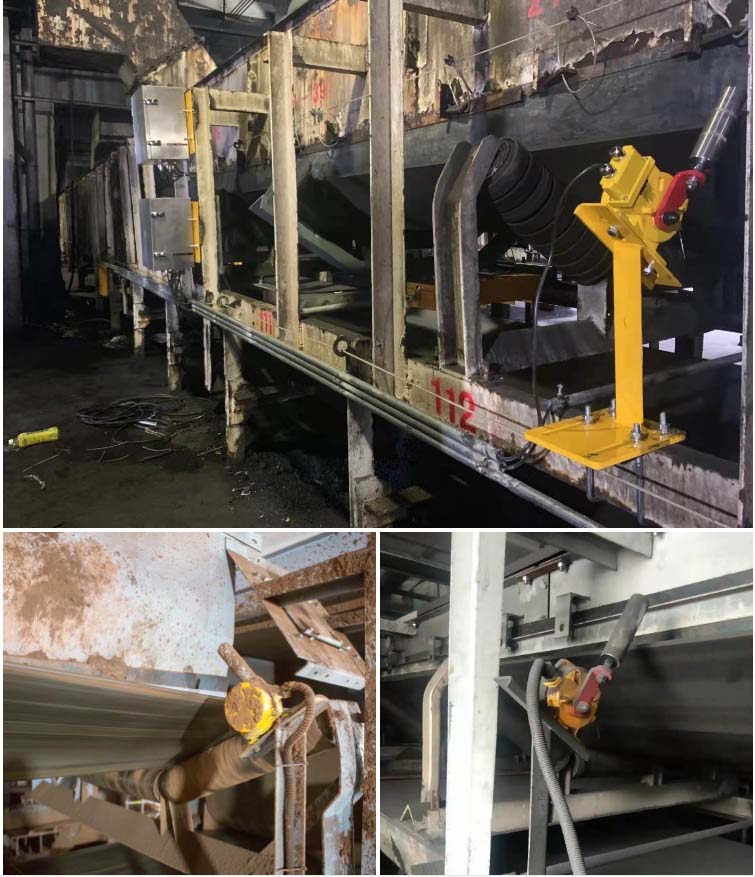

- The bidirectional rope switch is widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, chemical industry, etc., including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacking/reclaiming conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other types of conveyors. {$InfoTitle}

Description

HFKLT2-1 and HFKLT2-2 bidirectional drawstring switches

HFKLT2-1, HFKLT2-2, Automatic Reset Rope Switch, Manual Reset Rope Switch< Br/>

Our company's independently developed rope switches are automatic reset rope switches and manual reset rope switches. The protection level has reached IP67, which can completely prevent the entry of dust and water erosion< Br/>

The pull rope switch is installed on both sides of the belt conveyor and connected with a steel wire rope. When an emergency occurs in the conveyor belt equipment, the steel wire rope is pulled at any location along the site. The steel wire rope drives the drive arm to rotate, and the precision cam is displaced by the torque spring driven by the transmission shaft. The micro switch is driven to cut off the control line, and the conveyor stops running. Release the steel wire rope, and the switch contacts will automatically return to the original set position< Br/>

The pull rope switch and the use of internationally leading dual bearing transmission structure prevent the transmission shaft from directly rubbing against the housing or shaft sleeve during switch operation, resulting in increased clearance, loose sealing or jamming, greatly extending the service life of the switch. This switch has the characteristics of easy operation and no need for human supervision. However, after automatic reset, there may be a risk of false start, posing a threat to the safety of maintenance personnel< Br/>

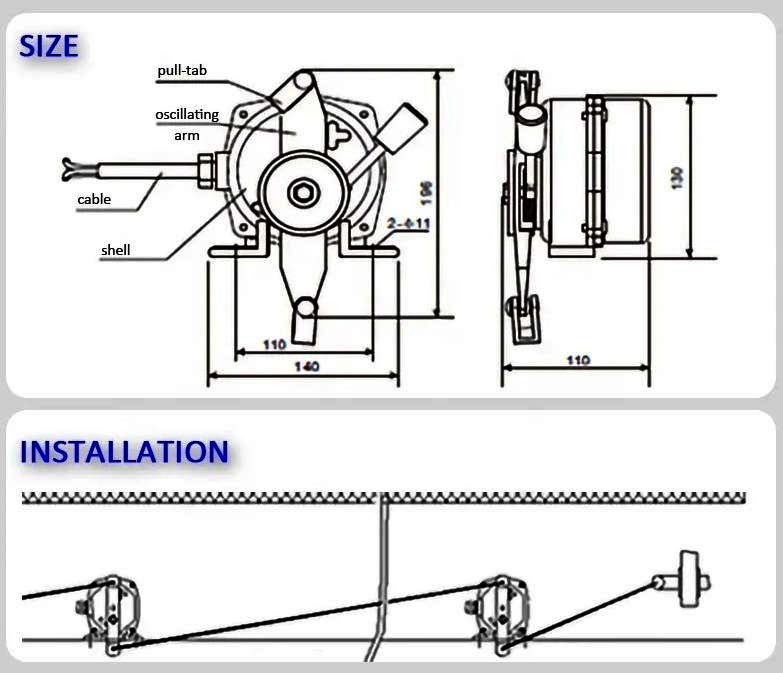

Installation method:

The rope switch should be installed in a location with maintenance channels on both sides of the conveyor, and the installation position should ensure that maintenance personnel can operate conveniently in emergency situations< Br/>

1. Fix the rope switch on the rack< Br/>

2. The distance between the two switches on one side is about 50m, using a diameter ofΦ The steel wire rope connection of 4 should have moderate elasticity< Br/>

3. To reduce the impact of the weight of the steel wire rope on the start of the switch, a support ring is installed on the frame every 3 meters to support the steel wire rope< Br/>

4. The other end of the steel wire rope is tied to the tension spring (fixed with a rope buckle), and the tension on both sides of the rope is tightened using a tightener without affecting normal use, ensuring that the tension on both sides is balanced< Br/>

(Note: For uphill conveyor machines, the switch spacing and rope length should be minimized as much as possible.)

Product parameters:

Protection level: IP67

Shell material: Precision baked paint on the surface of aluminum alloy

Required tension of cable: 49± 10N (5± 1kgf)

Connection point: 2

Contact capacity: 250V AC 5A

Wiring port: 6-12mm cable

Applicable temperature: -20 ℃~+60 ℃

Transmission rod material: stainless steel

Service life: 500000 times

&Nbsp;

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)