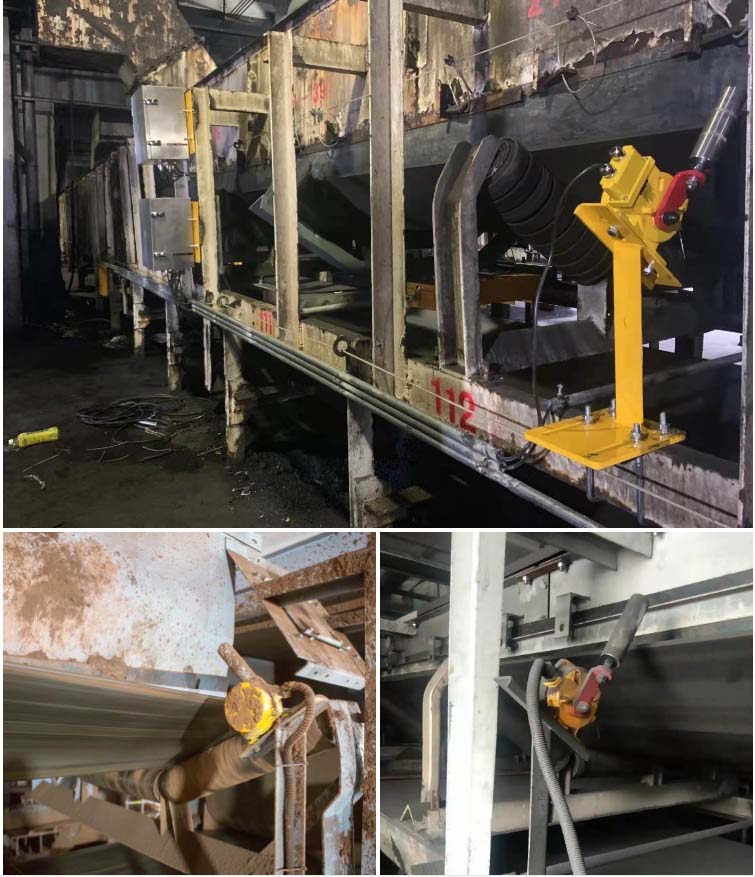

Stainless steel bidirectional rope switch

The stainless steel pull cord switch is made of stainless steel material by die-casting, with high strength to ensure rust resistance. It has an IP67 protection level and good sealing performance of the entire machine, which can work normally in a submerged state. This machine is used for emergency stopping of tape conveyors in case of accidents.

- ZXLS-220

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

- The bidirectional rope switch is widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, chemical industry, etc., including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacking/reclaiming conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other types of conveyors. {$InfoTitle}

Description

Stainless steel rope switch ZXLS-220

This machine is made of stainless steel material by die-casting, with high strength, non rusting, IP67 protection level, and good sealing performance of the entire machine. This machine is used for emergency stopping of tape conveyors in case of accidents. This machine is suitable for maintaining normal operation in environments with temperatures ranging from -25 ℃ to+55 ℃ and relative humidity not exceeding 85 ℃< Br/>

Structural characteristics of stainless steel rope switch ZXLS-220

This machine adopts a stainless steel die-casting shell with high strength, heavy weight, and a protection level of IP67. It can work in harsh environments for a long time. The machine adopts an imported travel switch, which has a large contact capacity and sensitive action. Reliable, can achieve one-time investment, lifelong benefits, and reduce maintenance intensity< Br/>

Technical parameters:

Environmental conditions for use:

Environmental temperature: -30 ℃ -+75 ℃

Relative humidity: not greater than 85

Action angle: 30 degrees

Extreme angle: 75 degrees

Action force: 10kg

Number of contacts: Normally open 1 (2) Normally closed 1 (2)

Contact capacity: manual reset and automatic reset

Reliability: 1000000 times

Weight: 3.5kg

Installation and use:

The switch is installed smoothly on the fixed bracket of the rack,

Tie the steel wire rope to the pull rings at both ends, with each side of the rope not exceeding 25-30 meters in length (if there is a slope, it should be shortened to 25 meters)

The pulling force of the rope should be appropriate to ensure the reliable reset of the switch< Br/>

The steel wire rope is set parallel to the tape, with a lifting ring added every 5 meters< Br/>

&Nbsp;

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)