Tuning fork level gauge

The working principle of a tuning fork level gauge uses a sensing element in the shape of a tuning fork, which has two sharp teeth inserted into the chamber or tank where the target medium will be present. The tuning fork sensing element vibrates at its natural resonance frequency by establishing motion within the sensing element or tuning fork. In the most common implementation of the working principle of a vibrating fork level switch, the harmonic vibration of the tuning fork sensing element is established using piezoelectric technology.

- YC series

- ZHUOXIN

- 220VAC 24VDC

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

- The working principle of the tuning fork level gauge is simple and effective. This makes the vibrating fork type liquid level switch (also known as the tuning fork type liquid level sensor) reliable, cost-effective, and very popular in detecting the presence or absence of liquids and large solid materials. The working principle of a vibrating fork type liquid level switch is based on detecting changes in the harmonic vibration frequency of the sensing element caused by the presence of the target medium.

Description

The working principle of a tuning fork level gauge uses a sensing element in the shape of a tuning fork, which has two sharp teeth inserted into the chamber or tank where the target medium will be present. The tuning fork sensing element vibrates at its natural resonance frequency by establishing motion within the sensing element or tuning fork. In the most common implementation of the working principle of a vibrating fork level switch, the harmonic vibration of the tuning fork sensing element is established using piezoelectric technology< Br/>

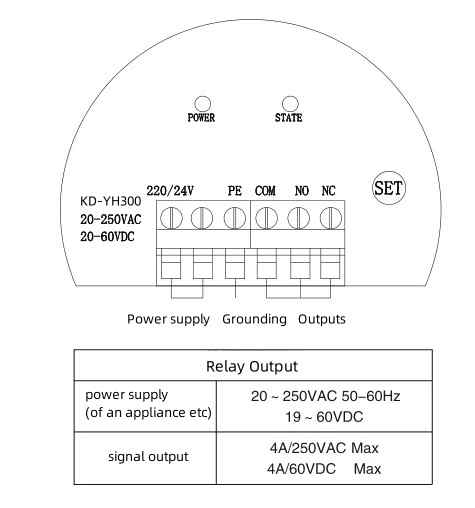

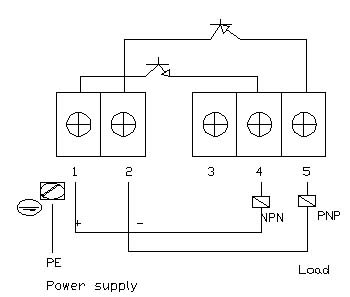

Power 19… 60VDC 19… 250VAC 50/60Hz

Switching time in the medium is 2 seconds, empty: 3 seconds

Environmental temperature -40&hellip+ 70° C

Shelf temperature -40&hellip+ 85° C

Medium temperature -40&hellip+ 150° C

Working temperature -1&hellip+ 40bar

Media type powder and particles=10mm, density> 0.1g/cm3

Liquid, viscosity=10000mm2/s, density> 0.7g/cm3

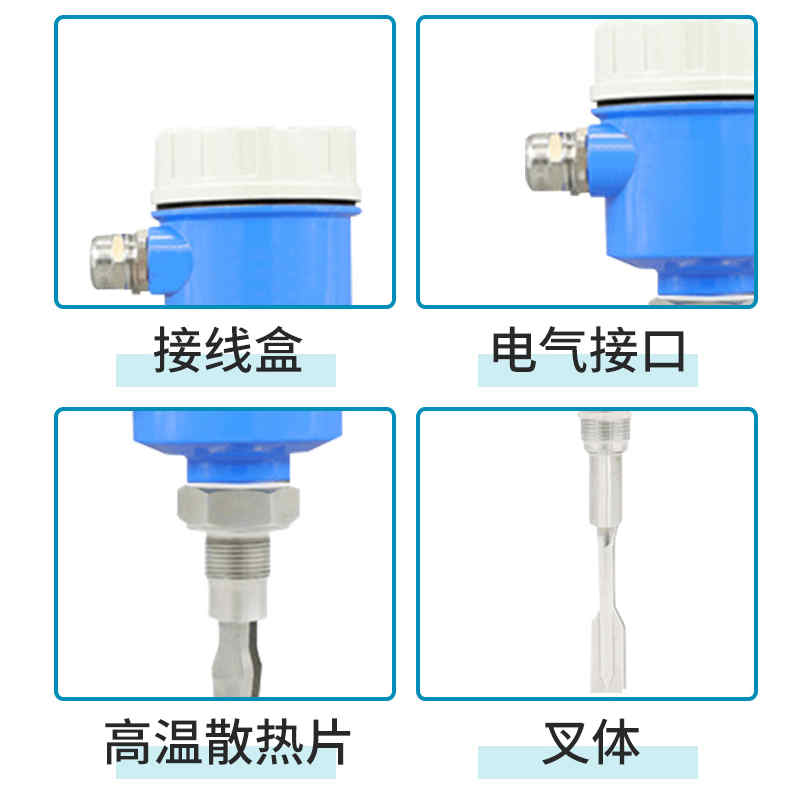

Process connector G1-1/2< Br/>

Electrical connection M12× P1.0 connector

Shell material SS304

Fork material SS304/SS316

Output relay, AC250V/4A, DC60V/4A

NPN, 400mA

PNP, 400mA

Power consumption DC < 3W, AC < 15W

Setting guide:

1) Insert the fork into the medium to be tested at a depth of approximately 10mm, and press&quo; SET” Press the button until the red and greedy LEDs flash alternately at least 2 times, then release the button; SET” Press the key, at which point the red LED flashes, then press&quo; SET” The button, red and greedy LEDS flash alternately, and then both light up< Br/>

2) Remove the fork from the medium, the green LED lights up, and the red LED goes off (NC closes through COM, NO and COM open). Now insert the fork into the medium again, and both LEDs light up (NO closes through COM, NC and COM open). Now the setup is complete< Br/>

Attention:

The default density of water is set to 1g/cm3, if the target medium density≥ 1g/cm3 does not require self inspection. When the target medium density< At 1g/cm3, a self check is required< Br/>

The default sensitivity is the highest. For materials with irregular surfaces and fluctuations, please set a lower sensitivity< Br/>

Avoid installing in locations with severe vibrations< Br/>

1

1&Nbsp;

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)