Tuning fork level switch

The tuning fork liquid level switch has strong adaptability: it does not affect electrical parameters and medium density, and is suitable for various conditions. Scaling, stirring, turbulence, bubbles, vibration, medium viscosity, high pressure, high temperature, etc.

- ZXYK series

- ZHUOXIN

- DC24V, AC220V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

- The working principle of the tuning fork level switch is simple and effective. This makes the vibrating fork type liquid level switch (also known as the tuning fork type liquid level sensor) reliable, cost-effective, and very popular in detecting the presence or absence of liquids and large solid materials. The working principle of a vibrating fork type liquid level switch is based on detecting changes in the harmonic vibration frequency of the sensing element caused by the presence of the target medium.

Description

The tuning fork level switch is suitable for solid and vibrating rod level switches. The tuning fork switch vibrates the tuning fork through piezoelectric crystals and the natural frequency of the tuning fork. It can continuously monitor changes in frequency< Br/>

When the tuning fork switch is used for low level alarm (or low level control), the medium in the container is discharged downwards through the tuning fork< Br/>

When it falls below a specific position and changes its natural frequency, this change is detected by electronic components, and the output state shifts; When used for high-level alarm (or high-level control), the medium in the container is upward and in contact with the tuning fork, which can change the output state. Changes are detected by intelligent circuits and converted into switch signals< Br/>

Application of tuning fork level switch:

Whether it's feed, slurry, or pulp, glue, or dye. The liquid level switches are all suitable

Water, mineral water

Wastewater, sewage, mud, acid-base solutions

Beer, beer fermentation agents, fruit juice, beverages

Materials with good fluidity such as paper scraps, glue, dyes, solid powders, etc

Diesel and other similar hazardous liquids/hazardous conditions

Features:

Strong adaptability: does not affect electrical parameters and medium density, suitable for various conditions. Scaling, stirring, turbulence, bubbles, vibration, medium viscosity, high pressure, high temperature, etc< Br/>

No calibration required: As it does not affect the electrical parameters and density of the medium, on-site calibration is not required

Maintenance free: No need to move parts, no maintenance required after installation< Br/>

Various power sources: The vibration fork liquid level switch is 20-250VAC, 20-60VDC, suitable for all power supply locations< Br/>

Various connections: liquid level switches with flange and threaded connections for your reference< Br/>

Power supply 20~60VDC 20~250VDC 50/60Hz

Power on time of 2 seconds when inputting materials

Environmental temperature -40~+70 ℃

Storage temperature -40~+85 ℃

Fluid temperature -40~+150 ℃

Work pressure -1~+40bar

Suitable medium powder and particles=10mm, density> 0.1g/cm

Liquid, viscosity=10000mm2/s, density> 0.7g/cm3

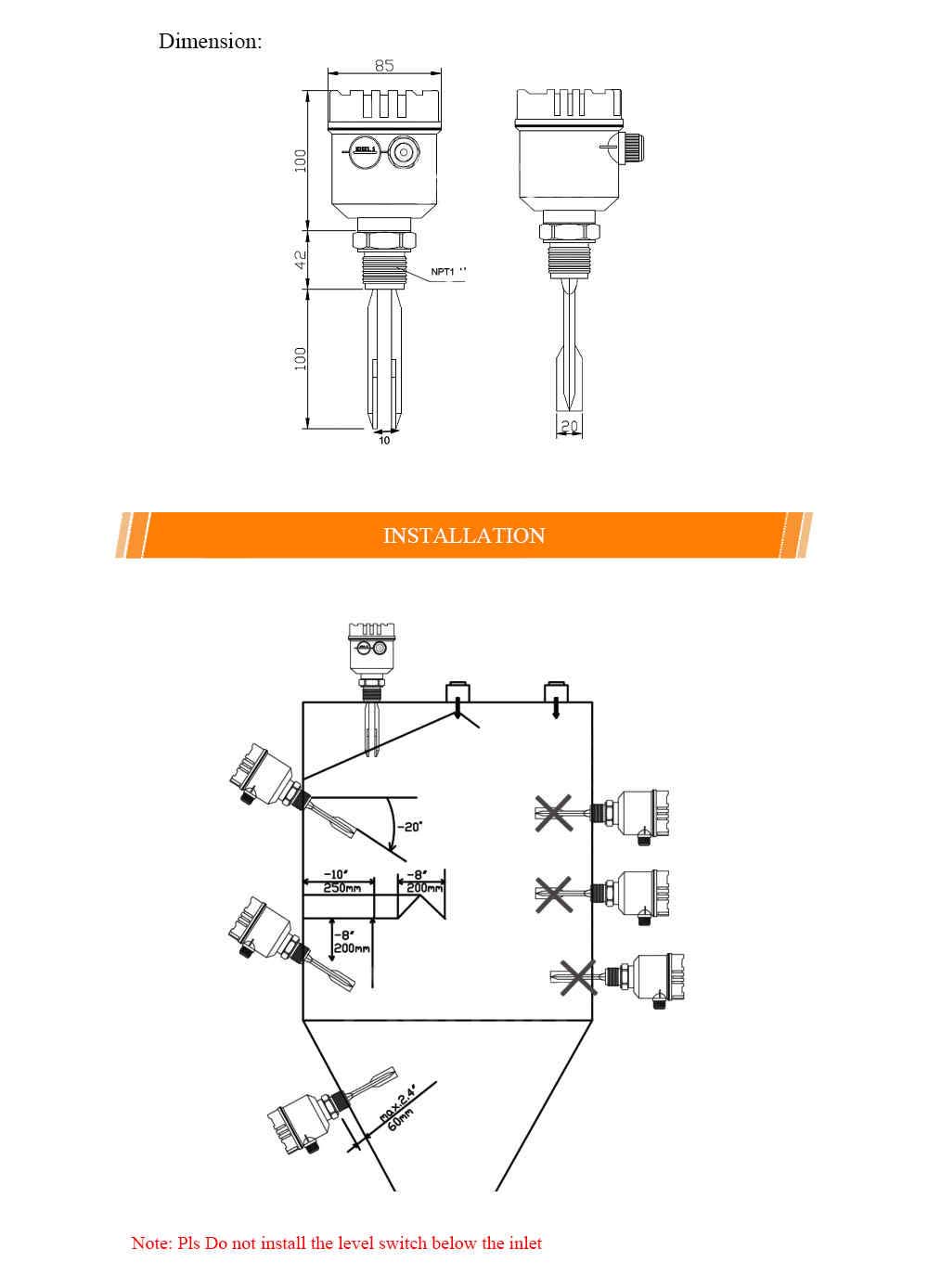

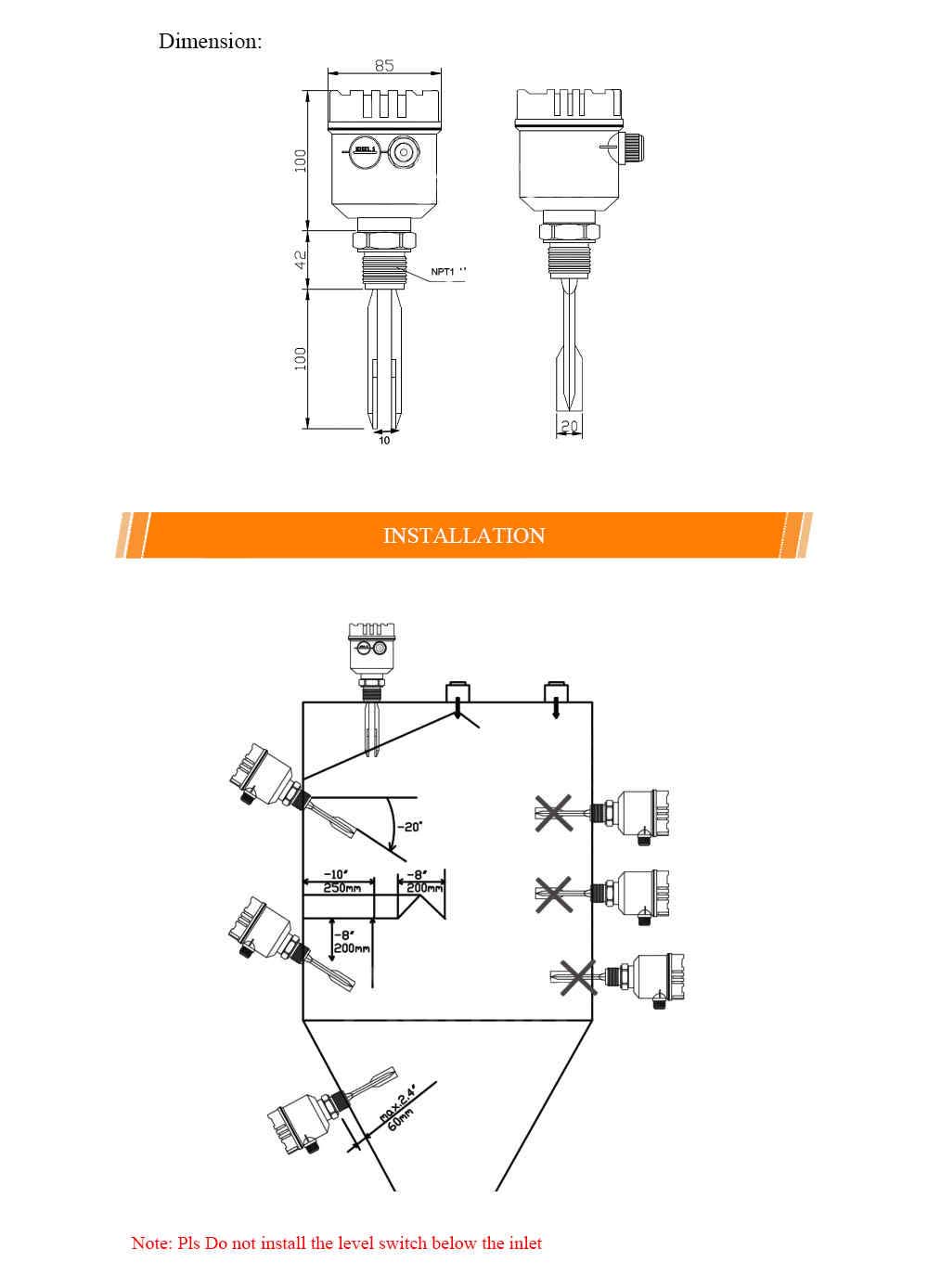

Connection method G1-1/2; G1&rdquo< Br/>

Electrical connection M12× P1.0 connector

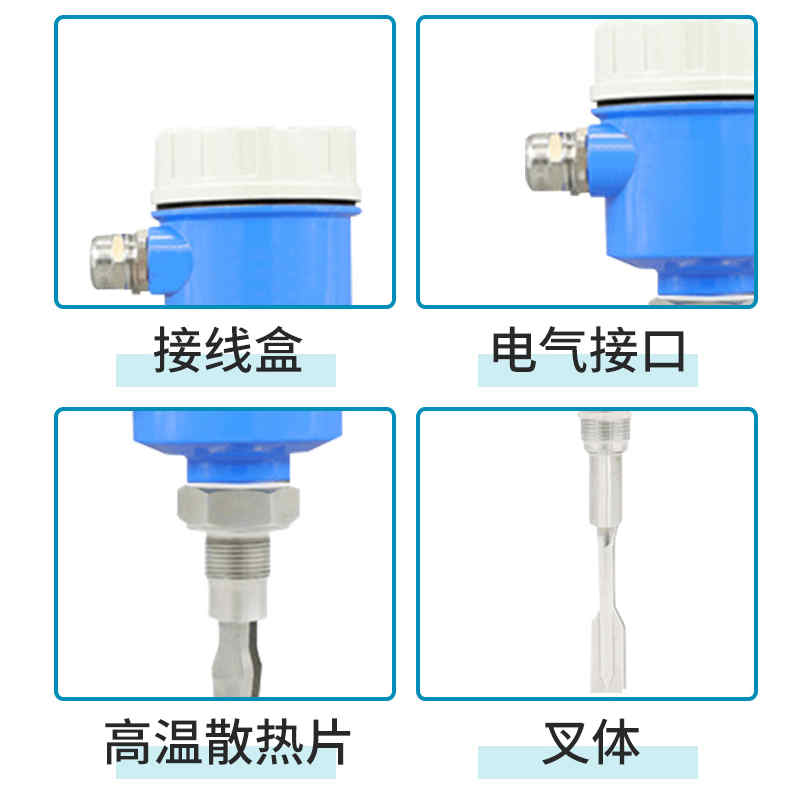

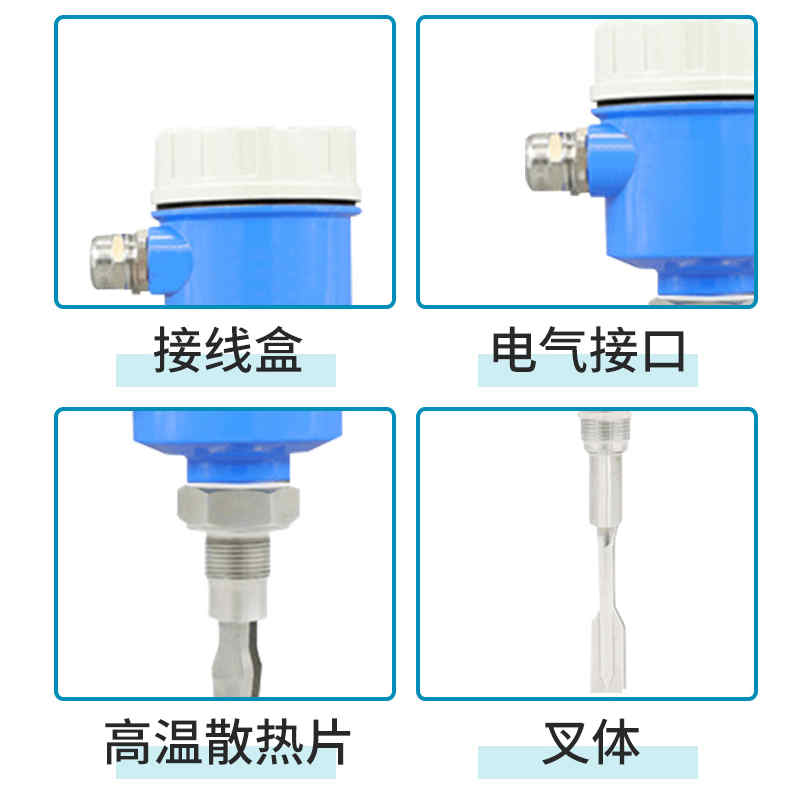

Shell material ABS aluminum alloy

Fork material stainless steel S304/SS316

Output relay output, AC250V/4A, DC60V/4A

Open collector gate (NPN) output, minus 400mA

Open collector (PNP) output, minus 400mA

Power consumption DC power, maximum 3W, maximum AC power 15W

&Nbsp;

When the tuning fork switch is used for low level alarm (or low level control), the medium in the container is discharged downwards through the tuning fork< Br/>

When it falls below a specific position and changes its natural frequency, this change is detected by electronic components, and the output state shifts; When used for high-level alarm (or high-level control), the medium in the container is upward and in contact with the tuning fork, which can change the output state. Changes are detected by intelligent circuits and converted into switch signals< Br/>

Application of tuning fork level switch:

Whether it's feed, slurry, or pulp, glue, or dye. The liquid level switches are all suitable

Water, mineral water

Wastewater, sewage, mud, acid-base solutions

Beer, beer fermentation agents, fruit juice, beverages

Materials with good fluidity such as paper scraps, glue, dyes, solid powders, etc

Diesel and other similar hazardous liquids/hazardous conditions

Features:

Strong adaptability: does not affect electrical parameters and medium density, suitable for various conditions. Scaling, stirring, turbulence, bubbles, vibration, medium viscosity, high pressure, high temperature, etc< Br/>

No calibration required: As it does not affect the electrical parameters and density of the medium, on-site calibration is not required

Maintenance free: No need to move parts, no maintenance required after installation< Br/>

Various power sources: The vibration fork liquid level switch is 20-250VAC, 20-60VDC, suitable for all power supply locations< Br/>

Various connections: liquid level switches with flange and threaded connections for your reference< Br/>

Power supply 20~60VDC 20~250VDC 50/60Hz

Power on time of 2 seconds when inputting materials

Environmental temperature -40~+70 ℃

Storage temperature -40~+85 ℃

Fluid temperature -40~+150 ℃

Work pressure -1~+40bar

Suitable medium powder and particles=10mm, density> 0.1g/cm

Liquid, viscosity=10000mm2/s, density> 0.7g/cm3

Connection method G1-1/2; G1&rdquo< Br/>

Electrical connection M12× P1.0 connector

Shell material ABS aluminum alloy

Fork material stainless steel S304/SS316

Output relay output, AC250V/4A, DC60V/4A

Open collector gate (NPN) output, minus 400mA

Open collector (PNP) output, minus 400mA

Power consumption DC power, maximum 3W, maximum AC power 15W

&Nbsp;

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)